Automatic drinking water dispenser for school community factory

Dimension: 75*65*180cm

Shell Material: 1.2mm galvanized plate

Capacity: 400 gallons and 800 gallons (Coin type and paper money) or customized.

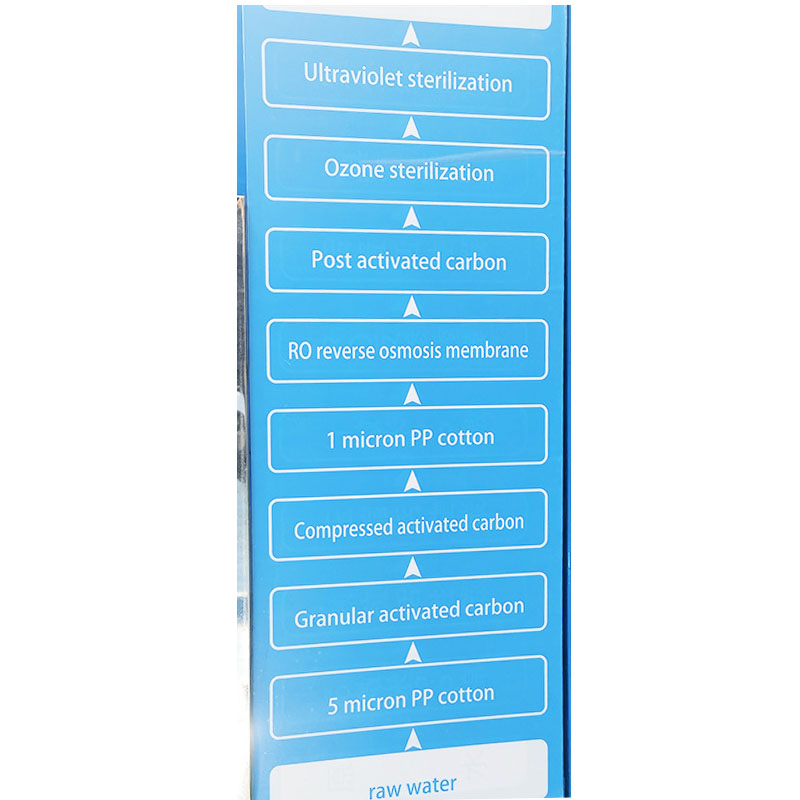

Treating process: Raw water---5 micro PP cotton---Granular activated carbon---Compressed Activated Carbon--1 micro PP cotton ---RO reverse osmosis membrane--Post Activated Carbon--Ozone Sterilization--Ultraviolet Sterilization

Applications: Large capacity water storage can meet the intensive population drinking water

1. School

2. Countryside

3. Factory

4. Community

5. Some other places

Process main Steps:

1. 5 micro PP cotton: remove large particles of impurities, colloids, silt, rust.

2. Granular activated carbon: remove residual chlorine, organic matter, odor, discoloration.

3. Compressed Activated Carbon: remove residual chlorine, organic matter, odor, discoloration.

4. 1 micro PP cotton: remove fine magazines, particles, colloids.

5. RO reverse osmosis membrane: remove TDS, heavy metals, bacteria, viruses, organic matter.

6. Post Activated Carbon: improve taste, chlorine, odor, discoloration.

7. Ozone Sterilization: Disinfect and sterilize the water inside the storage tank.

8. Ultraviolet sterilization: disinfect before water, thoroughly remove bacteria from water to ensure safety. For the water inlet external irradiation sterilization, effectively prevent the water inlet from being infected by bacteria.